Testing the Various Levels of Water Within a Well Bore

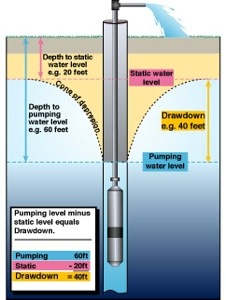

The Reason someone would be Testing the Various Levels of Water Within a Well Bore is to make sure the well has proper drawdown. Histories are created over time and valuable information gathered to create a nice bar graph of drawdown that will indicate drought effects on shallow wells. Sometimes a new pumping plan may need to be drawn.

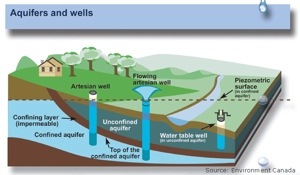

A lot of folks ask why in the world would someone use a shallow well for commercial use, when a solid aquifer exists at 600 ft? Also why would they use a jet pump as opposed to a submersible pump? The answers are simple (for me anyway)…

The Lowcountry Santee Limestone Aquifer has lots of water, but is just about unusable due to sodium chloride contamination, amongst other issues. On the other hand, Shallow wells are relatively sodium chloride free, most of the time. Santee limestone wells should be approximately 600 foot deep. A shallow well may only be as deep as 30 to 65 ft. If a large enough diameter casing is utilized on a shallow well, a submersible pump can be used. The problem with this is most shallow wells don’t create enough flow for the submersible pump. This will create a situation where the pump will use more water than the well may provide, and this will create excessive drawdown and possibly cavitation.

I have also seen shallow wells that produce lots of flow initially, But when a submersible pump with a vented casing is used, the oxygen mixes with the minerals in the water creating a clogged screen, possible bacteria issues and definite flow issues.

So rather than take a chance on issues such as these long-term… Most folks in the Lowcountry choose to use shallow wells with jet pumps. I have seen a lot of systems that pulled directly off of the well casing. Most of the time we construct any commercial shallow well 2 inches diameter. This allows us to use a drop pipe that is sealed to the casing… We may then add a valve to the top of that gives us access to the wellbore for chemical use or for testing purposes…

Over the years we have found that some drillers will use a blank piece of pipe on the bottom of their screen (for what ever reason we’re not sure-charge by the foot?). This may create a place for bacteria to grow and which is very difficult to treat by top chlorinating the well. By utilizing a tube that extends from the surface all the way down to the very bottom of the well you allow for chemicals to be put in the very bottom of the well… We utilize a tube that is approximately a half inch in diameter. This allows us access for the chemicals and as a result also a nice test port for water level indication…

Below is a video of testing for water level indication on a small diameter shallow well:

For deep wells it is actually easier to access well bore, sterilize and test than a shallow well. Most Deep wells are vented, which usually means there is direct access to the inside of casing. Water tables are usually monitored using electronic sound wave testers. Some guys still utilize older methods such as a physical tape measure or weighted string. We don’t recommend these methods anymore since there is a chance something could become wedged or lost inside the well.

Below is a picture of a submersible pump inside a well and how the water table reacts to pumping.